IGNITION AND MODBUS POLL SERIAL

MODBUS RTUcommand mode (HEX), you can control a variety of ways: Serial Hyper Terminal Control (need to manually add the CRC), Modbus Poll software control (software automatically add the CRC), PLC or MCU process controlġ DC 12V control circuit,Wiring diagram below. 7 Under the MODBUS command mode, it can support up to 64 devices in parallel 8 Size: 180* 90* 20mm 9 Weight: 296g 10 Maximum load: 10A / 250VAC, 10A / 125VAC For more information, please contact me Application Automated industry PLC Smart Home,Home Automation ,Wiser Home PTCCamera Security Monitoring Identification system Motor FW & BW LEDHome lighting 2: Standby current (all relays closed) 9MA, all 32 relay open 1150mA 3: ''open'' ''close'' ''Momentary'' ''Self-locking'' ''Interlock'' ''Delay'' 6 Commands 4: MODBUS RTU command 5: Under the ''Delay'' command ,the maximum delay is 255 seconds 6 MODBUS commands can be made serial HyperTerminal (serial assistant) OR ''Modbus Poll'' Enter.

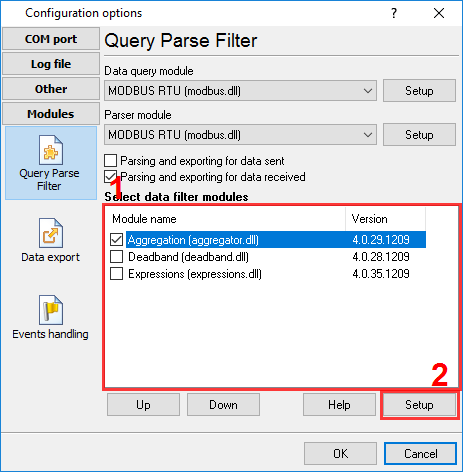

I'm going to try to put the word order back to normal in ignition and then use the registers on Page D-11.Product Name: R421C32 DC 12V 32 ChannelsModbusRTU RS485 Bus Relay Module UART Serial port Board for PLC LED Home automation door lock Package inlcuded: 1 xDC 12V 32 Channels R-S485 Modbus RTU Relay Module Description: 1: DC 12V power supply. What that does tell me is that everything else is working, it is definitely some part of the interface with Ignition. The data in the NuFlos is being accessed across the Digi's via the network for use in ILink on a realtime basis and they don't want me to upset that link. Due to a variety of factors, I can't actually do that. I did try Modbus Poll, but the documentation for that program specifically states that the modbus devices need to be pulled off of any other network in order to test them. So I tried selecting reverse word order and I'm getting the same symptom. The Modbus specification does not include a section for reading and writing 32bit values and as a result device manufacturers have implemented both methods." By checking this option, the high word will come before the low word. Then, in Ignitions documentation, you get this: "When reading and writing 32bit values from/to a Modbus device, the low word comes before the high word. I noticed, specifically, the part about "The standard word ordring for multiple register data types.is for the most significant word to appear first in the message." It all makes more sense to me on each reading. Read it first yesterday, and then some more last night, and then again this morning. I don't mean to sound ungrateful, because I definitely appreciate the confirmation, but I've read all of that.

They will probably initiate a GoTo Meeting session and look at your configuration. They will not ask for a support contract # before helping you with the issue. Your best bet would be to call Inductive Automation tech support so they can see what is going on. Does anyone recognize this symptom and have a good direction to point me in? I didn't leave it in place long enough to watch it go up and down. These new numbers immediately started the same upwards tracking/counting. So, I tried that option in Ignition and ended up getting wildly ridiculous numbers (in the millions or billions). As I understand it, if you use the F suffix on a Modbus Register in Wonderware, you're identifying it as a 32-bit floating point number. However, when he sets it up in Wonderware, he uses the F suffix (because that is how they have their own meters addressed). So the issue is not the meter or the Digi, it is something in Ignition. The really strange thing is, we have a sister platform that uses Wonderware, and when a friend pulled the data into Wonderware, it came in perfectly clear. This happens with every relevant register address.

IGNITION AND MODBUS POLL FULL

I know that the range it is counting up and down with is the full range of a modbus register, but I don't know why it's scanning like that.

Once the tag starts polling the register, it starts at zero, counts up to 32767, suddenly changes to -32767 and counts back down to zero. I can also create tags that poll the registers inside the flow analyzers. I can poll the Digi via Ignition by creating tags that are linked to the Digi's internal diagnostics.

IGNITION AND MODBUS POLL SERIES

We have a series of flow analyzers that are connected to the network via Digi-Iaps. I'm having a strange issue that I just cannot solve.

0 kommentar(er)

0 kommentar(er)